Latest News

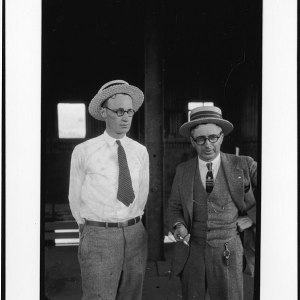

Vintage Views: The ugliest dog wins

Vintage Views: The ugliest dog wins

Opinion: Monkey Trial centennial

Opinion: Monkey Trial centennial

Canterbury honors ‘real heroes’ with updated Military Veterans’ Project

Their names, written in John Goegel’s angular script, form tight rows of capital letters like a precision font: Benjamin and Joseph Sanborn, both veterans of the War of 1812. Peter Ayres, a teenage soldier in the American Revolution.

Homeyer: July flowers worth growing

July is a great month for blossoms – but only if you have planned for that to happen. Many gardeners go to their local nurseries in May and June, selecting plants in full bloom. But when July comes along, those gardeners are tired or hot or at the lake or in the mountains, and forget to keep on buying plants. Not me. July is a great month for blossoms – on trees, shrubs and perennials. Here are a few of my favorite July plants.

Most Read

Warner shot down a housing developer’s bid. New statewide zoning mandates could clear a path for proposals like it.

Warner shot down a housing developer’s bid. New statewide zoning mandates could clear a path for proposals like it.

How fast will NH’s universal school choice program grow?

How fast will NH’s universal school choice program grow?

Federal government to appeal New Hampshire judge’s ruling on legal status of Dartmouth international student

Federal government to appeal New Hampshire judge’s ruling on legal status of Dartmouth international student

‘There’s tradition up here’ – Morrill Farm approaches its centennial, celebrates evolution and growth

‘There’s tradition up here’ – Morrill Farm approaches its centennial, celebrates evolution and growth

AROUND CONCORD: Your guide to free summer music

AROUND CONCORD: Your guide to free summer music

‘It's borderline criminal’ – Manufactured housing was an affordable homeownership option. Now, investor-owned parks are pricing residents out

‘It's borderline criminal’ – Manufactured housing was an affordable homeownership option. Now, investor-owned parks are pricing residents out

Editors Picks

A Webster property was sold for unpaid taxes in 2021. Now, the former owner wants his money back

A Webster property was sold for unpaid taxes in 2021. Now, the former owner wants his money back

Report to Readers: Your support helps us produce impactful reporting

Report to Readers: Your support helps us produce impactful reporting

City prepares to clear, clean longstanding encampments in Healy Park

City prepares to clear, clean longstanding encampments in Healy Park

Productive or poisonous? Yearslong clubhouse fight ends with council approval

Productive or poisonous? Yearslong clubhouse fight ends with council approval

Sports

Sunapee’s Bryce Whitlow keeps memory of above-average MLB players alive through social media page ‘MLB Hall of (Pretty) Good’

Bryce Whitlow has worked as a paraeducator in Sunapee for two years, but outside of his day job, he’s the man behind a social media page called “MLB Hall of (Pretty) Good” that has taken online baseball media by storm.

Concord Monitor Spring Players of the Season

Concord Monitor Spring Players of the Season

Opinion

Opinion: What Coolidge’s century-old decision can teach us today

One hundred years ago this July, a quiet man from Vermont — Calvin Coolidge — made a decision that changed the course of Sino-American relations.

Opinion: The art of diplomacy

Opinion: The art of diplomacy

Opinion: After Roe: Three years of resistance, care and community

Opinion: After Roe: Three years of resistance, care and community

Opinion: Iran and Gaza: A U.S. foreign policy of barbarism

Opinion: Iran and Gaza: A U.S. foreign policy of barbarism

Opinion: There’s no place like firearms-free zones

Opinion: There’s no place like firearms-free zones

Your Daily Puzzles

An approachable redesign to a classic. Explore our "hints."

A quick daily flip. Finally, someone cracked the code on digital jigsaw puzzles.

Chess but with chaos: Every day is a unique, wacky board.

Word search but as a strategy game. Clearing the board feels really good.

Align the letters in just the right way to spell a word. And then more words.

Politics

New Hampshire school phone ban could be among strictest in the country

When Gov. Kelly Ayotte called on the state legislature to pass a school phone ban in January, the pivotal question wasn’t whether the widely popular policy would pass but how far it would go.

Sununu decides he won’t run for Senate despite praise from Trump

Sununu decides he won’t run for Senate despite praise from Trump

Arts & Life

AROUND CONCORD: Your guide to free summer music

With a good camp chair, a cool beverage and a worn, cozy sweatshirt, the perfect New England summer evening might just be enjoying the music of local musicians at dusk.

Around Concord: Refreshing recipes from Table Bakery

Around Concord: Refreshing recipes from Table Bakery

The Rebel Collective to perform in Henniker

The Rebel Collective to perform in Henniker

Meet Moriah Billups, Young Professional of the Year

Meet Moriah Billups, Young Professional of the Year

Artist spotlight: Leah Kuehne

Artist spotlight: Leah Kuehne

Obituaries

Rose De Lima Locke

Rose De Lima Locke

Concord, NH - Rose de Lima Locke, 72, died May 2, 2025, after a long illness. She graduated from Ste. Marie High School. She worked at GE over 40 years and made many wonderful friends. She loved her family and friends. She loved her cat... remainder of obit for Rose De Lima Locke

Joseph Wyatt

Joseph Wyatt

Loudon, NH - Joseph (Joe) Robert Wyatt, 45, of Loudon, NH passed away unexpectedly on June 25, 2025. Joe was born May 24, 1980 in Concord NH. Joe grew up in Loudon and was a graduate at Merrimack Valley High School. He dedicated his ti... remainder of obit for Joseph Wyatt

Mark Saltsman

Mark Saltsman

Milton, FL - Mark Saltsman "Papa Salt" 67, passed away on June 18, 2025, in Atlanta GA. He left behind a wife, Teresa, 3 children, Dan, Tyler, and Nicolle and 4 grandchildren, Boaz, Storm, Sunrise, and Ellie. Mark had an unwavering love... remainder of obit for Mark Saltsman

Winston H. McCarty

Winston H. McCarty

Tilton, NH - Winston 'Win' Herbert McCarty died on June 26, 2025, at the New Hampshire Veterans Home, following a heart attack. At the time of his passing, he was surrounded by family, caregivers and fellow veterans. He was 96. Wins... remainder of obit for Winston H. McCarty

As Concord’s Gavin Richardson places second at golf Junior Amateur, young players look ahead to the 122nd State Amateur Championship

As Concord’s Gavin Richardson places second at golf Junior Amateur, young players look ahead to the 122nd State Amateur Championship

Around Concord: Steps to nowhere – but it used to be somewhere

Around Concord: Steps to nowhere – but it used to be somewhere

Six local seniors play in CHaD East-West All-Star Football game; Nyhan wins MVP

Six local seniors play in CHaD East-West All-Star Football game; Nyhan wins MVP Athlete of the Week: Nate Kiah, Bow Falcons

Athlete of the Week: Nate Kiah, Bow Falcons Track & field: Hopkinton’s Lane wins New England title in 3,200 meters, Concord’s Saysaw runs state record times in 100 and 200

Track & field: Hopkinton’s Lane wins New England title in 3,200 meters, Concord’s Saysaw runs state record times in 100 and 200 Concord became a Housing Champion. Now, state lawmakers could eliminate the funding.

Concord became a Housing Champion. Now, state lawmakers could eliminate the funding. ‘A wild accusation’: House votes to nix Child Advocate after Rep. suggests legislative interference

‘A wild accusation’: House votes to nix Child Advocate after Rep. suggests legislative interference  Town elections offer preview of citizenship voting rules being considered nationwide

Town elections offer preview of citizenship voting rules being considered nationwide