Latest News

Artist Spotlight: Brittany Batchelder

Artist Spotlight: Brittany Batchelder

Fire at Bradford house kills four pets

Fire at Bradford house kills four pets

Penacook parade to commemorate Memorial Day

Penacook parade to commemorate Memorial Day

‘You made a difference’ — Belmont baseball seniors honor their educators

Jennifer Deware smiled as she carefully threw the first pitch from the pitcher’s mound. The Belmont High School baseball team watched from the sidelines as five more educators did the same.

A soggy spring continues

Our soggy spring hasn’t let up this week, and we’ll likely get more rain on Friday and possibly this weekend. Memorial Day showers remain a possibility as of midday Thursday, but by all accounts, next week is shaping up to be a nice one with temperatures in the high 60s and low-70s and dry skies through Thursday. Weather, Page A8

Most Read

By all appearances, Canadians are leery of coming to NH

By all appearances, Canadians are leery of coming to NH

As Canadian travel to the U.S. falls, North Country businesses are eyeing this Victoria Day weekend to predict impacts in New Hampshire

As Canadian travel to the U.S. falls, North Country businesses are eyeing this Victoria Day weekend to predict impacts in New Hampshire

Catherine Masterson named next superintendent of Merrimack Valley and Andover starting in 2026

Catherine Masterson named next superintendent of Merrimack Valley and Andover starting in 2026

“A dream come true” – Family opens housing for adults with disabilities in Concord

“A dream come true” – Family opens housing for adults with disabilities in Concord

Helen Hanks resigns as Department of Corrections commissioner

Helen Hanks resigns as Department of Corrections commissioner

‘I thought we had some more time’ – Coping with the murder-suicide of a young Pembroke mother and son

‘I thought we had some more time’ – Coping with the murder-suicide of a young Pembroke mother and son

Editors Picks

The Monitor’s guide to the New Hampshire legislature

The Monitor’s guide to the New Hampshire legislature

One year after UNH protest, new police body camera footage casts doubt on assault charges against students

One year after UNH protest, new police body camera footage casts doubt on assault charges against students

‘It’s always there’: 50 years after Vietnam War’s end, a Concord veteran recalls his work to honor those who fought

‘It’s always there’: 50 years after Vietnam War’s end, a Concord veteran recalls his work to honor those who fought

‘We honor your death’ – Arranging services for those who die while homeless in Concord

‘We honor your death’ – Arranging services for those who die while homeless in Concord

Sports

High schools: Freitas 1-hitter leads Hopkinton softball to shutout; Tuesday’s baseball, lax, tennis and track results

Hopkinton 5, Kearsarge 0

Opinion

Opinion: Unfair taxes, unfair schools: The New Hampshire way

Ted Morgan is a retired professor of political science living in Tamworth.

Opinion: In the fight to stop sexual violence, can polio hold the solutions?

Opinion: In the fight to stop sexual violence, can polio hold the solutions?

Opinion: Where are the permanent solutions for a more stable budget?

Opinion: Where are the permanent solutions for a more stable budget?

Opinion: My memories of Vietnam 50 years later

Opinion: My memories of Vietnam 50 years later

Opinion: Concord officials: Can we sit and talk?

Opinion: Concord officials: Can we sit and talk?

Your Daily Puzzles

An approachable redesign to a classic. Explore our "hints."

A quick daily flip. Finally, someone cracked the code on digital jigsaw puzzles.

Chess but with chaos: Every day is a unique, wacky board.

Word search but as a strategy game. Clearing the board feels really good.

Align the letters in just the right way to spell a word. And then more words.

Politics

‘A wild accusation’: House votes to nix Child Advocate after Rep. suggests legislative interference

Rosemarie Rung thinks of Elijah Lewis often.

Sununu decides he won’t run for Senate despite praise from Trump

Sununu decides he won’t run for Senate despite praise from Trump

Arts & Life

Young Professional of the Month Katie Duncan shares about creativity, community, connection

Meet Katie Duncan, Membership Manager and Educational Outreach Coordinator at the Capitol Center for the Arts. The 35-year old Concord resident’s passion for the arts and the Concord community shines through her work. From theater stages to local lakes, Katie shares how growing up in Greater Concord shaped her path—and why she’s dedicated to giving back.

Tiny Tapestry sale at Red River Theaters raising money for Concord Coalition to End Homelessness

Tiny Tapestry sale at Red River Theaters raising money for Concord Coalition to End Homelessness

Bowling for a cause: Angelman Syndrome Fundraiser coming to Boutwell’s

Bowling for a cause: Angelman Syndrome Fundraiser coming to Boutwell’s

Beautify Allenstown hosting community cleanup day

Beautify Allenstown hosting community cleanup day

Donating “The Bibliophile”

Donating “The Bibliophile”

Obituaries

Roger Lincoln Sullivan

Roger Lincoln Sullivan

New London, NH - Roger Lincoln Sullivan, 85, of Clover Lane, died Sunday, May 18, 2025 at his home. He was born in Bridgeport, CT on February 12, 1940 the son of Albert L. and Edith (Riley) Sullivan. Roger was raised in Stratford, ... remainder of obit for Roger Lincoln Sullivan

James Richard Mikesell

James Richard Mikesell

James "Jim" Richard Mikesell Concord, NH - James Richard Mikesell, 82, a resident of Concord, NH, passed away on May 9, 2025, surrounded by his loving family. He was born on May 30, 1942, to his late parents, Reuben Byron and Mary Ellen ... remainder of obit for James Richard Mikesell

Timothy Harkness

Timothy Harkness

Lakeland, FL - Tim Harkness, age 61, of Lakeland, FL passed away peacefully on April 30, 2025. He was born on July 30, 1963 in Vermont and grew up in Epsom, NH. He had moved to Florida in 2018. He had always loved cars and had multiple ... remainder of obit for Timothy Harkness

Cody Chamberlain

Cody Chamberlain

Franklin, NH - It is with great sadness that we announce the unexpected passing of Cody James Chamberlain on May 17, 2025, at the age of 28 due to a motorcycle accident. Cody was born on July 29, 1996, and was the beloved son of Win... remainder of obit for Cody Chamberlain

N.E. will have enough electricity this summer but future winters may start to get dicey

N.E. will have enough electricity this summer but future winters may start to get dicey

N.H. Senate passes bathroom bill, sending it to Ayotte’s desk

N.H. Senate passes bathroom bill, sending it to Ayotte’s desk

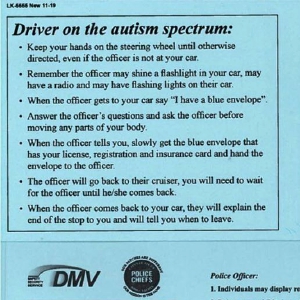

Blue Envelope program to start next year, promising safer police interactions during traffic stops in New Hampshire

Blue Envelope program to start next year, promising safer police interactions during traffic stops in New Hampshire

Girls’ lacrosse: Bow bounces back with 13-3 win over Bishop Brady

Girls’ lacrosse: Bow bounces back with 13-3 win over Bishop Brady

High schools: John Stark’s Philibotte pitches shutout, hits game-winning RBI in 1-0 win, plus more results from Wednesday

High schools: John Stark’s Philibotte pitches shutout, hits game-winning RBI in 1-0 win, plus more results from Wednesday

High schools: Belmont’s Divers pitches perfect game; Monday’s baseball, softball, lacrosse and tennis results

High schools: Belmont’s Divers pitches perfect game; Monday’s baseball, softball, lacrosse and tennis results High schools: Pelletier scores 100th goal, leads Concord girls’ lax to first win; baseball, softball, boys’ lacrosse and track results from this weekend

High schools: Pelletier scores 100th goal, leads Concord girls’ lax to first win; baseball, softball, boys’ lacrosse and track results from this weekend Five former Concord Crush girls at St. Paul’s are soon to leave the nest to play NCAA Women’s Lacrosse

Five former Concord Crush girls at St. Paul’s are soon to leave the nest to play NCAA Women’s Lacrosse Boys’ tennis: Growing the sport, fun and pizza for a tight-knit Concord team on Senior Night

Boys’ tennis: Growing the sport, fun and pizza for a tight-knit Concord team on Senior Night Town elections offer preview of citizenship voting rules being considered nationwide

Town elections offer preview of citizenship voting rules being considered nationwide Medical aid in dying, education funding, transgender issues: What to look for in the State House this week

Medical aid in dying, education funding, transgender issues: What to look for in the State House this week On the Trail: Shaheen’s retirement sparks a competitive NH Senate race

On the Trail: Shaheen’s retirement sparks a competitive NH Senate race