Latest News

Opinion: “Lafayette, we are here”

Opinion: “Lafayette, we are here”

Sun Cookin’ with Rob Azevedo: A bad idea

Sun Cookin’ with Rob Azevedo: A bad idea

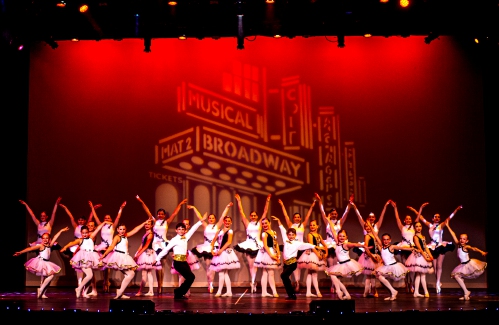

Preparing to say ‘I do’ – Inside the love story taking center stage at Market Days

Cady Hickman remembers the first time she saw Cameron Green’s smile.

‘A big step forward’: 26 new Americans celebrate earning their citizenship in Concord

Eritier Demunga’s mother brought him and his siblings from southern Africa to New Hampshire in 2013, hoping to give her children a better life. He was six years old at the time.

Most Read

Webster seized and sold his house for back taxes. Now the town has agreed to pay him $38,000

Webster seized and sold his house for back taxes. Now the town has agreed to pay him $38,000

A Webster property was sold for unpaid taxes in 2021. Now, the former owner wants his money back

A Webster property was sold for unpaid taxes in 2021. Now, the former owner wants his money back

‘The rug pulled out from under me’: For certain police and firefighters, last-minute changes to retirement deal breeds distrust

‘The rug pulled out from under me’: For certain police and firefighters, last-minute changes to retirement deal breeds distrust

Universal EFA program sees 2,000 applications in first week of expansion

Universal EFA program sees 2,000 applications in first week of expansion

Hillclimbs, nightlife and cruising: Enthusiasts flock to 102nd Laconia Motorcycle Week

Hillclimbs, nightlife and cruising: Enthusiasts flock to 102nd Laconia Motorcycle Week

Editors Picks

A Webster property was sold for unpaid taxes in 2021. Now, the former owner wants his money back

A Webster property was sold for unpaid taxes in 2021. Now, the former owner wants his money back

Inside EFAs: How school vouchers have fueled a Christian school enrollment boom in New Hampshire

Inside EFAs: How school vouchers have fueled a Christian school enrollment boom in New Hampshire

City prepares to clear, clean longstanding encampments in Healy Park

City prepares to clear, clean longstanding encampments in Healy Park

Productive or poisonous? Yearslong clubhouse fight ends with council approval

Productive or poisonous? Yearslong clubhouse fight ends with council approval

Sports

Athlete of the Week: Nate Kiah, Bow Falcons

Bow High School senior pitcher Nate Kiah had a stellar season on the mound and was a part of many deep playoff runs during his varsity career.

Opinion

Opinion: Outlines of a new dystopia

Opinion: Speechless in America no more

Opinion: Speechless in America no more

Opinion: Friends don’t let friends drive drunk

Opinion: Friends don’t let friends drive drunk

Opinion: Concord should be run like a household, not a business

Opinion: Concord should be run like a household, not a business

Your Daily Puzzles

An approachable redesign to a classic. Explore our "hints."

A quick daily flip. Finally, someone cracked the code on digital jigsaw puzzles.

Chess but with chaos: Every day is a unique, wacky board.

Word search but as a strategy game. Clearing the board feels really good.

Align the letters in just the right way to spell a word. And then more words.

Politics

New Hampshire school phone ban could be among strictest in the country

When Gov. Kelly Ayotte called on the state legislature to pass a school phone ban in January, the pivotal question wasn’t whether the widely popular policy would pass but how far it would go.

Sununu decides he won’t run for Senate despite praise from Trump

Sununu decides he won’t run for Senate despite praise from Trump

Arts & Life

Making music: Contoocook-raised Derek Astles celebrates new album, old collaborations

For Derek Astles, music offers a manual to the world.

“ON/OFF The Wall”: A new collaborative art exhibit

“ON/OFF The Wall”: A new collaborative art exhibit

Concord Hospital Health System welcomes New England College nursing cohort

Concord Hospital Health System welcomes New England College nursing cohort

High Range coming to Henniker Concert Series

High Range coming to Henniker Concert Series

Obituaries

Donald Soderstrom

Donald Soderstrom

Rockledge, FL - Donald Soderstrom, a Hall of Fame high school athlete, minor league baseball player, coach, and lifelong sportsman, passed away peacefully at his home in Rockledge, Florida, on June 15, 2025. He was 90. Born in Conco... remainder of obit for Donald Soderstrom

Howard David Bj Steinberg

Howard David Bj Steinberg

St. Petersburg, FL - Howard David BJ Steinberg favorite local musician, loving father, grandfather and husband passed away on June 3, 2025 in hospice care in St. Petersburg Florida. He was known for his incredible talent on guitar and p... remainder of obit for Howard David Bj Steinberg

Darrel Palmer

Darrel Palmer

Sutton, NH - Darrel Palmer, 85, formerly of Baker Road and Main Street, Andover, died Thursday, June 19, 2025. He was born in New London, NH on Dec. 11, 1939 the son of Ronald S. and Katherine M. (Merrill) Palmer. He graduated from New... remainder of obit for Darrel Palmer

Barry James Gruttemeyer

Barry James Gruttemeyer

Hopkinton, NH - Barry James Gruttemeyer, 73, longtime resident of Hopkinton, passed away on June 15, 2025, at the Concord Hospital with his wife and daughter by his side. He was born in Brooklyn, NY, on January 30, 1952, to his late par... remainder of obit for Barry James Gruttemeyer

Rally under the State House arch against potential U.S. involvement in the Israel-Iran conflict

Rally under the State House arch against potential U.S. involvement in the Israel-Iran conflict

Report to Readers: Your support helps us produce impactful reporting

Report to Readers: Your support helps us produce impactful reporting

City considers proposal for sanctioned homeless encampment

City considers proposal for sanctioned homeless encampment

Jones Field in Alton receives new CITGO sign replica from Stafford Oil

Jones Field in Alton receives new CITGO sign replica from Stafford Oil

Scott Kirby to bring a bit of Key West to Henniker

Scott Kirby to bring a bit of Key West to Henniker

Bell-to-bell school phone ban advances after budget deal

Bell-to-bell school phone ban advances after budget deal

Track & field: Hopkinton’s Lane wins New England title in 3,200 meters, Concord’s Saysaw runs state record times in 100 and 200

Track & field: Hopkinton’s Lane wins New England title in 3,200 meters, Concord’s Saysaw runs state record times in 100 and 200 Boys’ Lacrosse: Bears narrowly lose to Plymouth in D-III championship, 7-5

Boys’ Lacrosse: Bears narrowly lose to Plymouth in D-III championship, 7-5 Boys’ volleyball: Coe-Brown wins program’s first championship, completes perfect season

Boys’ volleyball: Coe-Brown wins program’s first championship, completes perfect season Baseball: John Stark falls in D-II championship to top-ranked Souhegan

Baseball: John Stark falls in D-II championship to top-ranked Souhegan Opinion: Our leaders’ puzzling decision to eliminate the State Council on the Arts

Opinion: Our leaders’ puzzling decision to eliminate the State Council on the Arts Concord became a Housing Champion. Now, state lawmakers could eliminate the funding.

Concord became a Housing Champion. Now, state lawmakers could eliminate the funding. ‘A wild accusation’: House votes to nix Child Advocate after Rep. suggests legislative interference

‘A wild accusation’: House votes to nix Child Advocate after Rep. suggests legislative interference  Town elections offer preview of citizenship voting rules being considered nationwide

Town elections offer preview of citizenship voting rules being considered nationwide 2025 Brodsky Prize for Excellence in Student Journalism awarded to Londonderry junior

2025 Brodsky Prize for Excellence in Student Journalism awarded to Londonderry junior